centrifugal flow compressor|advantages and disadvantages of a centrifugal compressor : China A centrifugal compressor is a type of dynamic compressor used to increase the pressure of a gas by converting its kinetic energy into potential energy. Commonly used in a variety of industrial applications to compress gasses . WEBCadastre-se na Deezer de graça e ouça MC Billy: discografia, top músicas e playlists.

{plog:ftitle_list}

WEB17 de fev. de 2024 · Minuto a Minuto. Campeonato Paulista. São Paulo. Meu time. 2. Fim de jogo. Bragantino. Meu time. Estádio Morumbi | 17/02/2024 18h00. 61% Posse de .

types of centrifugal compressors

Learn about the centrifugal compressor, a radial flow rotodynamic fluid machine that increases the pressure and velocity of air or gas by using mechanical energy. Find out its significance, features, working, components, types, applications, .centrifugal compressors have multiple impellers stacked together and connected by flow passages. Although centrifugal compressors are sometimes called radial compressors, most of the flow exiting a centrifugal impeller does not travel in a radial direction. Rather, the flow .

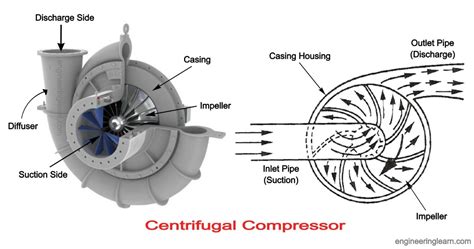

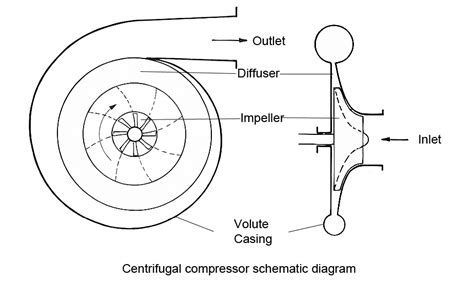

The basic concept of the centrifugal compressor is the use of centrifugal forces on the gas created by high velocity flow of the gas in the cylindrical housing. Figure 5-4 shows a diagram of a single-stage centrifugal compressor [2] .

how to test arm torsion strength

Learn how a centrifugal compressor compresses a fluid with the help of the impeller's radial acceleration and the diffuser's pressure conversion. Find out the components, types, advantages, disadvantages, and applications of centrifugal compressors.A centrifugal compressor is a type of dynamic compressor used to increase the pressure of a gas by converting its kinetic energy into potential energy. Commonly used in a variety of industrial applications to compress gasses .A Centrifugal compressor is dynamic turbomachinery that increases the pressure of a gas by adding kinetic energy through an impeller. The famous French genius, Professor Auguste Rateau, invented the centrifugal . Centrifugal compressors are used in those places where there is a need for steady and continuous flow. This makes centrifugal compressors a machine that has minimal noise and vibration. In other words, we can say that .

Centrifugal-Flow Compressors. Centrifugal compressors (Chapter 6) are used in small gas turbines and are the driven units in most gas turbine compressor trains. They are an integral part of the petrochemical industry, finding extensive use because of their smooth operation, large tolerance of process fluctuations, and their higher reliability . Centrifugal compressors elevate gas pressure by adding kinetic energy/velocity to the gas as it flows through an impeller. Kinetic energy increases potential energy/static pressure by slowing the flow through a diffuser. . The flow leaving the centrifugal impeller travels at an accelerated rate, until it flows through a stationary compressor .

Centrifugal compressors deliver high flow capacity per unit of installed space and weight, have good reliability, and require significantly less maintenance than reciprocating compressors. However, the performance characteristic of centrifugal compressors is more easily affected by changes in gas conditions than is the performance of .The centrifugal-flow compressor consists of an impeller (rotor), a diffuser (stator), and a compressor manifold. [Figure 1-46J Centrifugal compressors have a high pressure rise per stage that can be around 8:1. Generally centrifugal compressors are limited to two stages due to efficiency concerns. The two main functional elements are the .

A centrifugal flow compressor is designed to thrive in conditions that have higher capacities due to the continuous airflow through their multiple stages. In most cases, typical centrifugal air compressors have three stages within industrial plants. This is because air systems within plants need on average about an 8:1 pressure increase and . A centrifugal compressor is a type of dynamic compressor, or turbo compressor, with a radial design.Unlike displacement compressors that work at a constant flow, dynamic compressors work at a constant pressure and the performance is affected by external conditions such as changes in inlet temperatures. How Does a Centrifugal .Centrifugal compressor surge is an internal phenomena –and outlet flow rate is ZERO. centrifugal compressor surge is a characteristic behavior when inlet flow is reduced and the compressor head developed is so low that it can not overcome the pressure at the compressor discharge. (flow rate is ZERO.)Centrifugal and axial compressors produce a continuous flow of compressed gas thus producing typically insignificant amounts of low-frequency excitation in the fluid flow. However, some machines produce high-frequency excitations, between 1000 and 4500 Hz, depending on the size of the compressor, often excited by the interaction between .

Compressors fall into two broad categories. The first type of compressor is the centrifugal or annular compressor. Its impeller accelerates the flow by flinging it outward. This also increases the pressure. The pressure is increased further, and the flow is slowed, when the flow meets the diffusers that ring the impeller. Centrifugal air compressor delivered flow, or “capacity”, is dependent on inlet density. If the density drops due to higher inlet temperature, the volume flow actually reduces. The lower mass flow reduces the ability of the first stage impeller to develop velocity through momentum, and the inlet volume flow (in icfm or m3/hr) drops. .

In the throttle range of the compressor, these devices act to change the pressure the first-stage impeller sees. Density of the air decreases as the pressure drop increases. As the density decreases, the mass flow produced by the compressor also decreases. A centrifugal compressor can be throttled this way until the throttle surge point is reached.

1 College of Power and Energy Engineering, Harbin Engineering University, Harbin, China; 2 Dongfang Turbine Co., Ltd., Deyang, China; The present paper focuses on the optimization of large-flow coefficient centrifugal compressors, utilizing a mature centrifugal compressor impeller with a flow coefficient of 0.16 under design point condition in .

To provide high flow capability, our single-shaft centrifugal air compressor is built on a sturdy frame with proven compressor stage aerodynamics and interstage cooling. Designed for higher capacity, the single-shaft compressor is tailored to the needs of the air separation industry forFlow Rate: Centrifugal compressors are more suited to applications that require high continuous flow rates, given their continuous operation mode. Conversely, reciprocating compressors are better suited for low flow rate . The compressor on the right is called a centrifugal compressor because the flow through this compressor is turned perpendicular to the axis of rotation. Centrifugal compressors, which were used in the first jet engines, .These compressors have higher single-stage pressure ratios than axial compressors (typically 2 to 4 compared with ~1.25). As a result, centrifugal compressors have lower cross-sectional flow areas per mass flow rate than do axial compressors. They also have larger diameters but shorter lengths per unit mass flow rate than do axial compressors.

An animated simulation of an axial compressor. The static blades are the stators.. An axial compressor is a gas compressor that can continuously pressurize gases.It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially.This differs from other rotating compressors such as centrifugal . The process of dynamic compression, as applied in a centrifugal compressor operating stage, is velocity and kinetic energy converted to pressure and temperature as the flow is restricted. Another term for this process is mass flow – the power requirement to deliver the rated cfm of flow at the rated pressure (psig) is determined by the weight . A centrifugal compressor is a type of dynamic compressor used to increase the pressure of a gas by converting its kinetic energy into potential . This action reduces the pressure at the compressor discharge and increases the flow through the compressor, moving it away from the surge condition. Stabilization: By opening the anti-surge valve .

3hŸJ Ò(I3®±‘ Z¡ EB ôUq$¬MQÀ IŠ^ Vñ¤0llØ¢"ebn£#- fBÒYÌU) ‚ [ RL¡² m1.ŽQÈtôÝwtzôŠ^»ñ=^ææ ÿ†Ñ×tú ge¿ å ÅëÓóÓª?7`Q ß ÒyU¶¨÷ý. l¥ßóÓ[ÈЄ n S .The centrifugal-flow compressor consists of an impeller (rotor), a diffuser (stator), and a compressor manifold. [Figure 1] Centrifugal compressors have a high pressure rise per stage that can be around 8:1. Generally centrifugal compressors are limited to two stages due to efficiency concerns. The two main functional elements are the impeller .

A balancing drum is usually built into the compressor to counterbalance axial thrust. Axial compressors are generally smaller and lighter than their equivalent centrifugal compressors and normally operate at higher speeds. They are used for constant and high volume flow rates at a relatively moderate pressure, for instance, in ventilation systems.Ingersoll Rand manufacturers a innovative range of high-performance, reliable Centrifugal Compressors to suit your application needs. Click here to browse today Select Your Country/Region Current Region: USA (EN) Asia . higher flow and higher efficiency systems as well as process gas compression applications. As a company, we ensure superior .

Centrifugal compressors are dynamic, which means that compression is performed by converting kinetic energy into static energy. The characteristic of a centrifugal compressor is that the head is determined by the volume flow through the unit. A centrifugal compressor with an axial inlet (a typical full-wheel gearbox) uses a hose of the appropriate .The flow range of a centrifugal compressor is determined by the surge and choke points. Typical turndown for a fixed-speed, multi-stage centrifugal pump is approximately 20-30%. With variable speed drive or adjustable inlet guide vanes, the turndown can be increased to 40-50%.

how to test for sacral torsion

webTrapped in the Academy’s Eroge - Chapter 1. Read Trapped in the Academy’s Eroge - Chapter 1 with HD image quality and high loading speed at MangaJinx. And much more top manga are available here. You can use the Bookmark button to get notifications about the latest chapters next time when you come visit MangaJinx.

centrifugal flow compressor|advantages and disadvantages of a centrifugal compressor